Hot Form Tooling

Heat resistant materials (used for Aircraft Engine Components) have to be resistant to in-service temperatures exceeding 1000 deg. celcuis. The behavioural characteristics of these materials (Titanium, Inconel and Jet Heat) demand the forming of these parts at temperatures of between 600 deg. and upto 1000 deg. The tooling therefore has to equally withstand these temperatures during forming. High content Nickel / Chrome Steel has to be used in varying alloys to cope with these elevated temperatures.

Heat resistant materials (used for Aircraft Engine Components) have to be resistant to in-service temperatures exceeding 1000 deg. celcuis. The behavioural characteristics of these materials (Titanium, Inconel and Jet Heat) demand the forming of these parts at temperatures of between 600 deg. and upto 1000 deg. The tooling therefore has to equally withstand these temperatures during forming. High content Nickel / Chrome Steel has to be used in varying alloys to cope with these elevated temperatures.

Examples

-

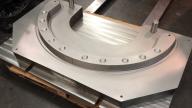

Ni/Cr Hot Draw Form Tool

Ni/Cr 3 Part Hot Draw Form Tool

Ni/Cr 3 Part Hot Draw Form Tool -

Hot Draw Form Tool

25/20 Cr/Ni - Hot Draw Form Tool

25/20 Cr/Ni - Hot Draw Form Tool -

Hot Form Tool

Punch / Ring

Punch / Ring -

Hot Form Tool

25/12 Ni/Cr Punch and Ring

25/12 Ni/Cr Punch and Ring -

25/20 Cr/Ni - Hot Draw Form Tool

25/20 Cr/Ni - Hot Draw Form Tooling

25/20 Cr/Ni - Hot Draw Form Tooling -

37/18 Ni/Cr Hot Draw Form Tool

37/18 Ni/Cr Tooling Design for customer approval

37/18 Ni/Cr Tooling Design for customer approval -

Hot Form Tool 18/8 Cr/Ni

Punch / Die Hot Crash Tool - Provided with tee slots (for clamping), blank location and thermo-couple points

Punch / Die Hot Crash Tool - Provided with tee slots (for clamping), blank location and thermo-couple points